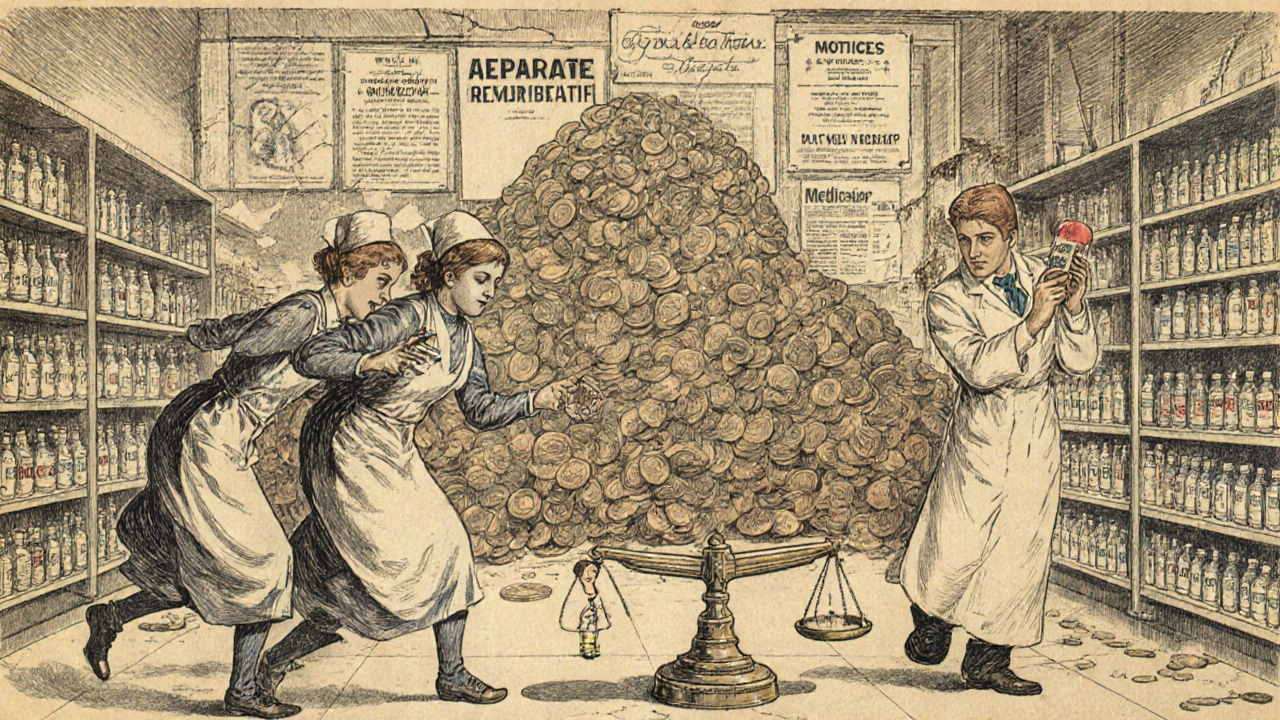

Drug shortages aren’t just a headline anymore-they’re a daily reality for hospitals, pharmacies, and patients. Behind every missing antibiotic, insulin vial, or chemotherapy drug is a manufacturer caught in a financial vice: rising costs on one side, capped prices on the other. And it’s getting worse.

Why Are Drug Prices Stuck While Costs Soar?

Generic drug makers are the backbone of the U.S. prescription system, supplying over 90% of all medications. But they operate on razor-thin margins-often less than 5%-and have no room to absorb shocks. In 2025, the cost of active pharmaceutical ingredients (APIs) jumped 18% year-over-year, according to the National Association of Manufacturers. That’s not a blip. That’s a tsunami.

Raw materials like benzene, acetone, and rare metal catalysts are now sourced from fewer countries due to trade restrictions. China and India still dominate API production, but export controls, tariffs, and political tensions have made supply unpredictable. A single port strike in Mumbai or a new tariff on Chinese chemicals can delay production for months.

Meanwhile, Medicare and Medicaid reimbursements haven’t budged. The Centers for Medicare & Medicaid Services (CMS) still pays the same rates for generic drugs it did in 2019. Private insurers negotiate hard, and big pharmacy benefit managers (PBMs) demand deeper discounts every year. Manufacturers can’t raise prices without losing contracts-or getting hit with regulatory scrutiny.

The Domino Effect: One Shortage, Hundreds of Impacts

When a single drug goes missing, it doesn’t just leave a gap. It cracks the whole system.

In Q2 2025, a shortage of injectable hydralazine-a blood pressure drug used in emergency rooms-forced 147 hospitals to switch to more expensive alternatives. The cost per dose jumped from $1.20 to $8.75. That’s a 629% increase. Patients waited longer. Nurses had to retrain. Pharmacies scrambled to find substitutes.

It’s not just injectables. Oral medications like levothyroxine, amoxicillin, and metformin have all seen disruptions. In some rural areas, patients are going without for weeks. The FDA recorded 312 active drug shortages in October 2025-the highest number since 2012. Of those, 89% were for generic drugs.

Manufacturers don’t just lose sales when they can’t produce. They lose trust. Hospitals start avoiding brands that frequently run out. Pharmacists switch to competitors. Once a reputation for unreliability sets in, it’s nearly impossible to recover.

Who’s Paying the Price?

It’s not the big pharma giants with billion-dollar R&D budgets. It’s the small and mid-sized manufacturers-the ones making the drugs that keep people alive every day.

A 2025 survey of 127 generic drug producers by the Generic Pharmaceutical Association found that 76% had cut R&D spending. 68% had delayed equipment upgrades. 53% had laid off staff. One company in Ohio shut down its entire sterile injectables line after three years of losses. They couldn’t afford to meet FDA compliance standards anymore.

These aren’t lazy companies. They’re survivors. Many have been making the same drug for 30 years. They don’t have marketing teams or lobbyists. They just make pills and hope the math works out.

Meanwhile, the cost of compliance is climbing. FDA inspections now cost manufacturers an average of $420,000 per facility. Quality control systems require new software, training, and audits. The FDA’s backlog of pending inspections grew by 34% in 2024. Waiting for approval means lost production time-and lost revenue.

Why Solutions Are Hard to Find

People talk about “fixing” drug shortages. But the fixes are messy, expensive, and slow.

Some manufacturers are trying dual-sourcing-getting APIs from two different countries. But that doubles the complexity. One supplier might be cheaper. The other might be slower. Both might be affected by the same geopolitical event.

Others are investing in nearshoring. A few companies have moved API production to Mexico or Eastern Europe. But the infrastructure isn’t there. Skilled labor is scarce. Equipment costs are higher. And it takes 18-24 months just to get a new line up and running.

Even if a company could raise prices, they’re locked in. Medicaid contracts are legally binding. Medicare pricing is set by formula. And if they raise prices too much, they risk being excluded from formularies-or worse, facing an investigation for price gouging.

What’s Working? A Few Bright Spots

Not all hope is lost. Some manufacturers are surviving by changing how they operate.

One company in Indiana started using real-time inventory tracking and AI-driven demand forecasting. Instead of guessing how much metformin to make, they now use hospital order patterns, pharmacy refill data, and even weather trends (flu season spikes demand) to adjust production. Their stockouts dropped by 61% in 12 months.

Another firm partnered with a local university to co-develop a new synthesis method for a critical antibiotic. The new process cut raw material use by 40% and reduced waste by 70%. It took two years and $11 million-but now they’re profitable again.

And then there’s the federal government. The Strategic National Stockpile has started stockpiling 12 high-demand generic drugs. It’s not enough, but it’s a start. The Inflation Reduction Act’s new drug pricing provisions have also created some breathing room for manufacturers producing older, low-margin drugs. For the first time, some are getting small subsidies to keep lines running.

What Comes Next?

Without structural change, the shortages will keep coming. And they’ll get worse.

Experts at MIT’s Center for Transportation and Logistics warn that if nothing changes, manufacturing inflation for drugs could stay 1.8 percentage points above pre-2020 levels through 2030. That means more shortages, more delays, and more patients going without.

But the path forward isn’t about blaming one side. It’s not just the manufacturers. It’s not just the government. It’s the entire system.

Patients need affordable drugs. Providers need reliable supply. Manufacturers need to make a living. And right now, none of those goals are aligned.

The only way out is to rebuild the economics of generic drug production. That means paying more for the drugs we rely on-or finding smarter ways to produce them. There’s no third option.

Why are generic drug shortages getting worse in 2025?

Generic drug shortages are worsening because manufacturers face rising costs for raw materials and compliance, while prices remain frozen due to government and insurer reimbursement caps. Trade restrictions, geopolitical instability, and supply chain fragility have made it harder to source key ingredients, and many small manufacturers can’t afford to absorb these losses or invest in alternatives.

Which drugs are most commonly in short supply right now?

As of October 2025, the most frequently短缺 drugs are injectables like hydralazine, epinephrine, and phenylephrine; antibiotics like amoxicillin and cefazolin; and chronic disease medications like levothyroxine, metformin, and insulin. These are all low-margin generics that rely on complex, global supply chains.

Can drug manufacturers just raise prices to cover costs?

Most can’t. Medicare and Medicaid reimbursement rates are fixed by law. Private insurers and pharmacy benefit managers (PBMs) demand deep discounts, and raising prices risks losing contracts or triggering regulatory investigations. Even when manufacturers try, the market often absorbs the increase, leaving them with no real profit gain.

What role do tariffs and trade policies play in drug shortages?

Tariffs on chemicals, metals, and packaging materials have increased input costs by 10-15% for many manufacturers. Trade restrictions on key suppliers in China and India have disrupted the flow of active pharmaceutical ingredients (APIs). Over 80 countries introduced new trade barriers between 2024 and 2025, making global sourcing riskier and more expensive.

Are there any government programs helping manufacturers stay open?

Yes, but they’re limited. The Strategic National Stockpile now stocks 12 critical generic drugs. The Inflation Reduction Act includes small subsidies for manufacturers producing older, low-margin drugs. Some state programs offer tax credits for nearshoring production. But these don’t cover the scale of the problem-only a fraction of struggling manufacturers qualify.

What can patients do if their medication is unavailable?

Patients should contact their pharmacist immediately-they may know of alternatives or be able to order from a different supplier. Some hospitals and clinics have emergency stockpiles. For chronic conditions, doctors can sometimes prescribe a therapeutically similar drug. Never stop taking a medication without consulting a provider. The FDA also maintains a public list of current shortages on its website.

Write a comment